Abstract

The coronavirus has created significant disruptions and exposed supply chain (SC) vulnerabilities. This crisis started a discussion about SC sustainability and performance. Therefore, the implementation of advanced technologies and supply chain collaboration could mitigate this disruption with the help of government support and policies. Considering this situation, this paper examines how COVID-19 influences advanced technologies (Artificial Intelligence, the Internet of Things, Blockchain, Digital twins, and Big Data Analytics) and supply chain collaboration (SCC) with a moderating role of government support and policies (GSP) in Pakistan. The study encompasses a comprehensive assessment carried out via structural equation modeling and data collected from Pakistani companies engaged in SCM or those operating within the SC divisions of manufacturing enterprises. According to the empirical findings, it is evident that COVID-19 outbreaks have a significant influence on SSCP; However, they do not show a similar impact on advanced technologies (AI, IoT, Blockchain, DT, and BDA) and supply chain collaboration, the influence of COVID-19 on SSCP was effectively mediated through advance technologies (AI, IoT, Blockchain, DT, and BDA) and supply chain collaboration. This research contributes to the existing literature on SSCP by emphasizing the importance of the resource-based view, dynamic capability view, and institutional theories. SC and logistics managers can apply the theoretical framework proposed in this study to mitigate the impact of the COVID-19 epidemic or disruptions in logistics and SC operations, thereby improving profitability in the context of an epidemic.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

COVID-19, a virus epidemic that began in 2019, is one of the most devastating in the recent past [1, 2]. It triggered the world’s worst financial collapse after the great depression and crippled every aspect of society and the economy [3,4,5]. As a result, COVID-19 directly influences the sustainable development targets set for 2030 [6].

The supply chain interruption associated with COVID-19 produced unusual issues worldwide, underlining the supply chain’s vital role in financial systems and societies [7]. Moreover, as stated by Fortune [8], over ninety-four per cent of 1000 business entities have experienced SC interruption due to COVID-19. Researchers have discussed that supply chains encounter the most substantial risks, which include high uncertainties, persistent disruptions, and the propagation of repercussions [7, 9]. Likewise, Min et al. [10] underlined that some enterprises had lost 80% of their revenue due to food SC impacted by lockout during the pandemic. The COVID-19 isolation and shutdown made reaching markets, items, and resources hard. For this purpose, production companies have been compelled to adopt novel regulations and rules, alter customer demands, and follow stringent operational practices due to the pandemic crisis to handle their supply chain operations more effectively and efficiently [11]. So, firms are being pressurized by their stakeholders for sustainable production [12] and adopting those practices which depict socially responsible behavior thereby achieving sustainable performance [13]. Therefore, scholars have highlighted the critical necessity for research focusing on the resilience and sustainability of supply chains [9, 14,15,16,17].

Many studies have explored the correlation between COVID-19 and SSCP to better understand their connection. For instance, research in a study conducted by El Baz and Ruel [18] in the coronavirus setting explored how crucial SC risk control is to minimize the impact of interruptions on SC resilience and consistency. Similarly, another research that was carried out by Basit et al. [19] investigated the connection between COVID-19 and SSCP with mediator management innovation, business model innovation, and knowledge management capability. However, no research has been discovered to determine and confirm the mediating roles of advance technologies (AI, IoT, Blockchain, DT, and BDA) and supply chain collaboration between COVID-19 and SSCP with the moderating role of government support and policies. Similarly, [20, 21] calls for empirical research on advance technology (AI, IoT, and BDA) to explain how firms facing the coronavirus threats might use the development of digital technologies to reduce the threats posed by the outbreak. In the COVID-19 setting, it is noted that digital technologies, such as 3D printing, video streaming, and cloud computing, contribute to enhancing supply chain sustainability [22,23,24]. Stević et al. [25] highlights that the SC collaboration strategy as the effective SCM strategy during COVID-19. According to Basit et al. [19] government needs to provide economic benefits and incentives to SC companies, like tax breaks, interest-free loans, and encourage for import of advanced technologies during COVID-19. Moreover, to improve an organization's performance, adopting new processes or adapting existing capabilities is imperative [15, 26]. In the COVID-19 context, businesses are required to strike a well-balanced approach between the triple bottom line (TBL) and sustainability, striving to exceed shareholder anticipations while simultaneously delivering favorable financial outcomes [27, 28].

Thus, our study's main goal is to investigate the following question.

-

1.

Does COVID-19 impact on sustainable supply chain performance?

-

2.

Does COVID-19 influence on advanced technologies (AI, IoT, Blockchain, DT, and BDA) and Supply chain collaboration?

-

3.

Do advanced technologies (AI, IoT, Blockchain, DT, and BDA) and Supply chain collaboration mediate the relationship between COVID-19 and SSCP?

-

4.

Does Government support and policies moderate the relationship between advanced technologies (AI, IoT, Blockchain, DT, and BDA) and Supply chain collaboration and SSCP?

This study seeks to address the identified gap by proposing a theoretical model and experimentally testing the advanced technologies (AI, IoT, Blockchain, DT, and BDA) and supply chain collaboration as mediating variables between COVID-19 and SSCP with the moderating role of governmental support and policies. To achieve this objective, numerous hypotheses are formulated relying on the Resource-Based View (RBV), Dynamic Capabilities View (DCV), and Institutional Theory (IT). RBV is a theoretical approach to dealing with the business environment turbulence arising from global expansion, digital innovation, and the financial crisis. Wernerfelt and Barney [29, 30]. In addition, RBV believes that organizations are a group of unique resources and competencies that underpin an organization's strategy and primary source of profitability [31]. Based on RBV, firms can deploy digital technologies to resolve interruptions [22]. DCV revolves around an organization's capacity to adjust, reconfigure, and innovate its assets in reaction to evolving environments. Teece et al. [32] have introduced DCV theory, emphasizing how firms develop capabilities to respond to immediate disruptions and continuously learn and evolve strategically over time. Institutional theory, a prominent framework in organizational sociology, delves into how external social, political, and cultural forces influence and shape organizational structures and behaviors [33]. It suggests that organizations obey to institutional pressures from their external environment, including governmental regulations, societal norms, and industry standards, to gain legitimacy and survival [34].

2 Literature review

2.1 COVID-19's influence on sustainable supply chain

According to Kähkönen et al. [35], the epidemic has influenced companies and communities; as a consequence, manufacturing and consumption shortages are an issue for the worldwide business community and have a long-lasting effect on the efficiency of SSCP. Similar to this research, the worldwide supply chain's availability has been influenced by the epidemic in several ways [36]. Additionally, both globally and locally, coronavirus plays a direct role in changes in supply and demand [37]. Similarly, Ali et al. and Sharma et al. [12, 38] declared that an outbreak of Coronavirus has negatively impacted the food supply system, resulting in an imbalance between supply and demand. Due to the inadequate organizational structure and limited resilience of the food supply chain, the situation grew worse. Alike Xu et al. [39] several industry sectors worldwide have suffered significant damage due to the COVID-19 epidemic. Therefore, it has heavily disrupted the distribution and accessibility of an extensive number of necessities, intermediate items, and finished goods. The GSCs, which have shown a strong level of robustness and resilience in the face of many disruption events for more than twenty years, are truly damaged. Similarly, the economy has been seriously damaged, and lives have been lost due to the COVID-19 outbreak. Due to the tightened shutdown, production and logistics operations have been postponed, impacting the Input and output of different goods [40].

H1: The COVID-19 outbreak has a negative effect on SSCP.

2.2 COVID-19 and advanced technologies (AI, IoT, Blockchain, DT and BDA)

According to Modgil et al. [41], artificial intelligence can improve SC flexibility transparency, allowing end-stage delivery and customized service solutions for upstream and downstream suppliers, reducing disruption impact, and enabling a flexible purchasing approach in COVID-19. Alike, Nayal et al. [42] revealed that SC integration, interchange of information, and procedural factors significantly influence Artificial intelligence implementation and, as a result, favorably reduce SC risks in Covid-19. During the period of COVID-19, AI could become a driving force for agricultural food supply in India and provide solutions to different agricultural challenges, such as labor support. In addition, for improved productivity and resource efficiency, smart farming can be made possible [43]. Besides, Zheng et al. [44] examines the link between supply chain flexibility and AI, identifies essential AI innovations that potentially improve resilience, and designs a technological structure for implementing AI into SC resilience. The slowing down of the economy and restrictions on trade have led to shortages and supply chain interruptions worldwide. Effective strategies are needed by businesses and their supply chains to handle these disruptions. To minimize and adapt to disruption, this investigation introduces a framework based on AI, the Blockchain, and BDA. Therefore, an AI-driven framework, Blockchain and Big Data Analytics is suggested by Wamba and Queiroz [45] in as a way of mitigating disruptions.

The COVID-19 epidemic has influenced the pharmaceutical SC, and Blockchain and Internet of Things technologies may be able to help the PSC become more effective and resilient. Additionally, these solutions increase the effectiveness of pharmaceutical supply chain operations in the information technology industry, handle complex problems, and raise the operations' visibility, adaptability, and transparency [46]. According to Yadav et al. [47], using an IoT monitoring system in the agriculture SC may increase consumer efficiency and sustainability, particularly during dangerous activities like COVID-19 outbreaks. Alike in agriculture food SCM, IoT can enhance the mechanism for coordinating the response to natural outbreaks [48]. Besides, Kumar et al. [49] revealed that digital technology, like IoT and Blockchain, could improve transparency and safety in several sectors, including the food SC during the epidemic. Moreover, digitalization and automation of all business activities deriving from the IoT are suggested by Končar et al. [50] to ensure that measures are complied with while maintaining a smooth operation of the SC in situations of a natural disaster. The IoT and Artificial Intelligence development have significantly impacted modern technology. As a result, IoT and AI participate more actively in SCM, especially throughout the epidemic [51].

Omar et al. [52] examine how the COVID-19 epidemic has influenced the healthcare SC tracking and management of personal protective equipment. Therefore, Blockchain technology integration in the SC can improve product tracking while preserving data reliability and authenticity. Alike, Kazancoglu et al. [53], sustainable food supply chains are susceptible, and reverse logistics practice operational management is required to establish robust SC against COVID-19. Therefore, the usage of Blockchain technology is also necessary to carry out reverse logistics operations in a food SC. Moreover, Iftekhar and Cui [54] investigated the use of blockchain technology powered by hyper ledger fabric and provided a clear manual for building a blockchain network to track and monitor the SC to alleviate the risks that an epidemic in the ice-covered meat business could cause. Likewise, Nandi et al. [55] discovered that implementing Blockchain technology improves SC adaptability and flexibility in times of crisis. Similar efforts were made to strengthen the SC and an automated framework for grocery delivery in the context of the pandemic. Besides, SC finance companies that use Blockchain technology are shielded during COVID-19 from such value loss and trade volatility. Therefore, Investor confidence in Blockchain also lessens market uncertainty [56]. Further, Ahmad et al. [57] has a Blockchain-based method to establish data authenticity for COVID-19 healthcare products and distribute them, automate advanced supply chain tasks, and streamline data interchange.

Big data analytics (BDA) solutions might be applied to supplier chains to help them recover and become more resilient during the Covid-19 era. In addition, they are improving their market position and developing inside and outside abilities by applying Big Data Analytics [58]. During COVID-19, Zhang et al. [59] highlighted that big data analytics, AI, and environmental monitoring play a strengthening role, to achieve market competitiveness, and increase the positive connection between environmental handling systems and green SCM. Similarly, during COVID-19, BDA played a vital part in the healthcare SC and helped to improve responsiveness, innovation, and resilience [60]. Besides, Nisar et al. [61] discovered that applying BDA might improve SC risk management and promote green product creation to accomplish SSCP. In addition to improving creativity and capability, SC risk management and green product development have a positive effect. According to Chatterjee et al. [62], SME innovation and technology capabilities positively impact supply chain capability, affecting SME performance during COVID-19. Global markets are vulnerable to sudden changes and unpredictability, particularly during situations like the epidemic. To get beyond these obstacles, Hasan et al. [63] found that SC managers should employ BDA to enhance their plans. Additionally, BDA supports supply chain firms in analyzing massive volumes of information to facilitate decision-making and operations.

H2a: The COVID-19 outbreak positively affects the adoption of advanced technologies.

2.3 COVID-19 and supply chain collaboration

The partnership involving the producer and seller within the supply chain contributes to averting the repercussions of the COVID-19 epidemic through observing health guidelines and maintaining social distancing. Furthermore, the vital elements for boosting customer confidence and enhancing public consciousness amidst the pandemic involve online retail, the enforcement of health guidelines, and health-oriented promotional initiatives [64]. According to Khuntia et al. [65], healthcare expenses are increasing, with a significant part of a hospital's spending directed toward supplies amid the COVID-19 pandemic. While collaboration remains a possibility, concentrating on and enhancing current integration dynamics proves beneficial for nurturing the expansion and services within healthcare systems [66]. Found that IT competency correlates with outer resilience, SC collaboration relates to inner resilience, their amalgamation is linked positively to external resilience, and inner resilience shows a positive association with company effectiveness during an epidemic. Amid the pandemic, shifts in SCs toward online shopping are evident, particularly with manufacturers also venturing into online sales. Therefore, Khodoomi et al. [64] discovered that within the health-social dual-channel SC, pricing strategies and SC collaboration are particularly profitable for retailers.

H2b: The COVID-19 outbreak positively affects the adoption of supply chain collaboration.

2.4 Advanced technologies (AI, IoT, Blockchain, DT, and BDA) and SSCP

Every business entity relies on an efficient supply chain to achieve success. Artificial intelligence enables businesses to forecast and project customer demand with almost 100% accuracy and improve their scientific discovery and production with reduced costs and higher quality. Provide better customer service (determining the pricing, establishing the target market, creating the perfect messaging, etc. [67, 68]. Alsharidah and Alazzawi [69] revealed that AI and digital evolution significantly and positively influence SCM in Saudi companies. Additionally, improved quality criteria, adaptability, effectiveness, and production are essential benefits of AI and the digital revolution. Benzidia et al. [70] highlight that BDA and AI tools have recently become increasingly popular among academics and professionals. In addition, using big data analytics and AI technologies is vital to environmental process combination and cooperation in global SCs. Likewise, Manning et al. [71] found that utilizing AI in food SC is growing and benefits users and society. In addition, particular aspects such as transparency, traceability, explanations, interpretations, accessibility, responsibility, and accountability can also be considered in the context of AI systems. AI and BDA influence humanitarian SCs' speed, resilience, and effectiveness. In addition, the humanitarian SC has reduced its level of information complexity in moving towards agility, resilience, and performance [72]. De Vass et al. [73] demonstrated that the capability of the IoT is beneficial and significant for internal, client, or supplier-related processes to affect the SC positively.

Rejeb et al. [74] argued that modern supply chains could be simplified and enhanced through Blockchain technology in conjunction with an Internet of Things infrastructure, thus increasing value chain networks. In addition, it can help to scale, info flows, transparency and integration, consistency, safety, and reliability. Likewise, Gnimpieba et al. [75] provides a framework for a collaboration platform built on cutting-edge technologies such as GPS/GPRS, CC, IoT, and RFID for locating, identification, interaction, monitoring, and data exchange to control the movement of commodities and improve cooperation and compatibility in the SC. Hastig and Sodhi [76] highlight that Blockchain applications are critical in supply chain traceability and some essential successful implementation aspects. Alike, Gurtu and Johny [77] revealed that Blockchain transparency, authenticity, trust, and safety, reduce costs, disintermediate, run efficiently, and minimize waste can revolutionize supply chain management. Moreover, all Blockchain-enabled transactions are more transparent, effective, secure, and economical [78]. So, it is a prevalent belief that blockchain-distributed nature helps to reduce supply chain risks [79]. Similarly, the supply chain’s adverse impacts are mitigated by Blockchain, reducing the interruptions brought on by shifting paradigms [80]. Moreover Kim and Laskowski [81], has shown that tracking constraints and ontologies on the Ethereum blockchain, blockchain technology, and IoTs help accurately attribute tangible products generated and distributed in complex, intra-organizational SC. Likewise, Engelenburg et al. [11] provides a blockchain framework designed to track the provenance of supply chains. This system securely stores essential data, provides role-based access, and encrypts it for maximum security.

Without a doubt, data is the foundation of practically all investigations and company operations. BDA is essential to SCM, logistics, and inventory management, as it optimizes business operations through customer behavior analysis [82]. Gunasekaran et al. [83] demonstrate that the commitment of upper-level management influences the positive connection between connectivity, information allocation, and the acceptance of BDA. Moreover, this acceptance is therefore favorably linked to integrating BDA through repurposing BDPA procedures. Ultimately, this assimilation positively impacts supply chain performance and the organization’s overall performance. Likewise, Roßmann [84] discovered that big data analytics would make demand forecasts more accurate, reduce safety stocks, and increase supplier performance management. As a result, supply chain management will become more efficient, partly replacing the tasks traditionally performed by supply chain management. According to Bag and Nicoletti [85, 86] there is an essential influence on creating new green products and the results of managing BDA for an SSC. The influence of BDA talent skills on staff growth and SSC results is less intense but still considerable. According to the literature examined above, we have developed the following hypothesis:

H3a: Advance technologies (AI, IoT, Blockchain, DT, and BDA) are positively correlated with SSCP.

2.5 Supply chain collaboration and SSCP

Collaboration significantly boosts information and resource sharing, resulting in positive effects on supply chain performance within Indonesia's fresh vegetable sector [87]. The stability of relationships between suppliers is affected by elements like the value of secure resources, shortages, and the initial mindset of suppliers toward collaboration. Moreover, sharing secure resources between competing suppliers can result in shared advantages and help mitigate the adverse consequences of supply chain disruptions [88]. Likewise, Goenka et al. [89] examined how the proficiency of individuals, cooperative efforts, and adaptable design influence the resilience of supply chains and the performance of businesses. It uses a questionnaire and SEM to validate hypotheses and finds that SC individual proficiency positively influences collaboration and adaptable design, which consequently has a beneficial effect on SC resilience and organizational performance. Moreover, Huo et al. [90] enhancing supplementary income, implementing reward and penalty systems, and optimizing synergy coefficients enhance the likelihood of the system progressing towards Pareto optimality and accelerate the achievement of extensive collaboration within the agricultural goods SC primarily led by farmer associations.

H3b: Supply chain collaboration is positively correlated with SSCP.

2.6 The mediating role of advanced technologies (AI, IoT, Blockchain, DT, and BDA) between COVID-19 and SSCP

In light of the recent SC interruption due to pandemics and crises, resilience and performance in this area are becoming increasingly relevant. Growing knowledge of modern information processing methods like AI for creating SCRs and improved supply chain performance has arisen within the context of digital transformation, connection, and worldwide in SC [91,92,93]. Moreover, Wang and Pan [94] revealed that during Covid-19, three key factors influencing AI technology adoption are relative advantages for enterprises, a collaboration between supply chains, and environmental uncertainty, which will ultimately contribute positively to logistics resilience and performance. The COVID-19 epidemic interrupted the worldwide SC and made its previously unknown flaws visible. Dubey et al. [95] found that the financial and operations result of the entity is enhanced by its ability to manage alliances to take advantage of the mediating influence of AI-driven SC Analytics. Researchers [42] demonstrate that adopting artificial intelligence has a crucial impact on process factors such as information exchange and integration into supply chains, which is beneficial for risk mitigation during Covid-19.

Goodarzian et al. [96] introduced a new vaccine SC distribution explicitly designed for the COVID-19 outbreak. The network considers different factors, e.g., waste treatment, environmental impact, and demand for coverage and vaccine delivery time. Therefore, IoT applications used to ensure accuracy, speed, and consistency in the distribution of vaccines are based on this network. During the COVID-19, the pharmaceutical SC has confronted significant challenges and risks. Chen et al. [46] revealed during COVID-19 that IoT and blockchain tools could benefit operations. Furthermore, technologies enhance SC operations’ efficiency, adaptability, and transparency. The outbreak of epidemics like COVID-19 poses unique risks to the global agriculture food SC (AFSC). The risk is due to the disruption of logistics networks, uncertainties in demand, and sustainability concerns. Therefore, to improve AFSC, Yadav et al. [97] has developed a sustainable multi-tier system using IoT technology. Similarly, for AFSC Yadav et al. [98] designed an IoT-based practical and helpful organizing system to enhance its capability under natural outbreaks.

The COVID-19 pandemic has made companies and communities more vulnerable to the shortcomings of typical consumption patterns, manufacturing, and supply chains. Nandi et al. [55] provide suggestions for strengthening supply chains’ transparency, resiliency, and sustainability by utilizing the potential of Blockchain and the capabilities of the circular economy principle. To facilitate information interchange between all parties engaged in the waste handling and control of coronavirus medical devices in a completely secure, transparent, traceable, and reliable way. Ahmad et al. [57] suggested implementing a decentralized blockchain-driven system. Also, include the Ethereum blockchain with IPFS’s decentralized preservation to safely acquire, store, and exchange information on the waste handling and control of coronavirus medical device forward supply chain. Nabipour and Ülkü [99], the COVID-19 epidemic has generated a variety of essential innovations, one of the most notable being the integration of blockchain technology into SCM. Evidently, a substantial link exists between the incorporation of Blockchain technologies and sustainability aspects, which extend to economic and waste-related dimensions within the setting of the COVID-19 epidemic.

Nisar et al. [61] revealed that corporations might strengthen their SSCP with greater concentration on BDA abilities, risk, and innovation in the post-COVID-19 situation. The capacity to analyze larger volumes of data is critical in SSCP. The COVID-19 outbreak has caused one of the worst SC interruptions in history, forcing professionals and academics to increase their capacity for resistance. As a result, Spieske and Birkel [100] showed that BDA is suitable for improving supply chain resistance. The COVID-19 outbreak has brought on significant SC interruptions. Thus, resilient corporations can overcome this unprecedented situation with effective strategies. Moreover, Yamin [101] highlighted that BDA, focusing on risk handling, SC communication, and leadership commitment, is required to improve SC resistance and accomplish efficient performance. To evaluate the influence of BDA capabilities on the improvement of coordination and operational adaptability within hospital supply chains, Yu et al. [102] presents a model grounded in the organizational information processing theory. Additionally, it is posited that the integration of hospital supply chains experiences a significant achieved by the incorporation of BDA. Consequently, we formulated the subsequent hypotheses from the literature we examined.

H4a: The COVID-19 outbreak and SSCP relationship are influenced by the mediation of advanced technologies (AI, IoT, Blockchain, DT, and BDA).

2.7 The mediating role of supply chain collaboration between COVID-19 and SSCP

The stability of supplier relationships is influenced by factors such as the value of secure resources, scarcity levels, and suppliers' initial inclination toward collaboration, where sharing these secure resources among competing suppliers can mutually benefit and mitigate SC interruption consequences [88]. During the epidemic, a noticeable trend toward online shopping is observed in supply chains, especially with manufacturers exploring online sales [13, 64] revealed that in the dual-channel SC focusing on health and social aspects, retailers can reap significant profits through effective pricing strategies and supply chain collaboration. Moreover, Takawira and Mutambara [103] revealed the significance of collaborative management of interruptions in the supply chain lies in promoting resilience by improving the exchange of information, coordinating planning efforts, and implementing mechanisms for sharing risks among partners to ensure a consistent provision of vital pharmaceuticals in the face of global crises. Sartika et al. [104] highlights the robustness of the beef dish sector amidst the COVID-19 pandemic, facilitating efficient collaboration throughout the supply chain. This cooperation entails the smooth exchange of information, financial transactions, and product distribution, with vertical coordination among raw material suppliers enhancing the delivery of beef dishes to end consumers. Therefore, we hypothesized that.

H4b: The COVID-19 outbreak and SSCP relationship are influenced by the mediation of supply chain collaboration.

2.8 The moderating role of government support and policies

Dubey et al. [105] Revealed that during COVID-19, government effectiveness, including measures such as tax credits, postponing interest payments, and investing in digital technologies is essential for strengthening SC resilience through the enhancement of digital flexibility and agility. Amid the COVID-19 crisis, governments globally are intensifying efforts to ensure the reliability of supply chains, particularly in securing medical equipment, vaccines, and maintaining stable food supplies, recognizing that disruptions have lasting economic consequences such as delays in essential components impacting productivity [106]. According to Chebo and Dhliwayo [107], throughout COVID-19, government financial support, policies, and guidelines significantly impact the acceptance of new technology, participation in volunteer programs, and principles and moral standards. The problem with financial and supply chain resources implies that seeking external assistance may be necessary to tackle numerous challenges. Therefore Paul et al. [108], highlights that governmental financial assistance might be essential to sustain the continuity of a SC until the crisis diminishes. Therefore, we hypothesized that

H5a: Government support and policies moderates the relationship between advanced technologies and SSCP.

H5b: Government support and policies moderates the relationship between supply chain collaboration and SSCP.

3 The data sources and research approach

Our study's main objective concerned gaining insights into how COVID-19 and the SSCP are related. Through a quantitative methodology that involved testing a hypothesis, we set out to achieve this aim effectively. To validate the accuracy of our hypothesis, we collected data from SC companies and the SC departments of manufacturing organizations that are registered with the Securities and Exchange Commission of Pakistan. For additional information, consult Table 1 for details regarding the demographics. In pursuit of these goals and objectives, the study utilizes five elements representing the constructs related to COVID-19, and the scale utilized in this research is derived from prior studies [18, 109]. We used five items to measure advanced technologies obtained from [110]. We evaluated the supply chain collaboration construct by utilizing five items sourced from [111]. We used five items for government support and policies adopted from [112, 113]. We used five items to measure SSCP obtained from [114, 115]. A summary of the questionnaires is demonstrated in Appendix. The surveys were sent to participants through email. Respondents utilized a Likert scale with five points, spanning from 1 (strongly disagree) to 5 (strongly agree) to answer the survey queries. Ultimately, a total of 329 responses were collected, with 28 of them being incomplete. Additionally, 301 surveys were considered appropriate for subsequent examination.

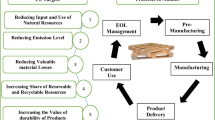

Our next step involved using econometric approaches after compiling comprehensive data on various factors. In addition, this enabled us to systematically analyze and establish connections between these constructs as part of our investigation [116]. Additionally, it enables the examination of interconnected constructs in a parallel manner [117]. Moreover, statistical tests have been conducted to determine a model adequate to examine different factors and constructs. Furthermore, the focus was on convergence and correlation validity criteria [117]. Figure 1 shows the suggested model.

Our approach for testing the research hypotheses of this study involved implementing the PLS-SEM technique with Smart PLS-4 Software. In management research, few methods can match the prowess of PLS-SEM when modelling complex cause-effect relationships. In addition, this technique is popular due to its long-established reputation for being exceedingly reliable and accurate [118]. Additionally, PLS-SEM provides superior resilience because it circumvents challenges associated with inadmissible or indeterminate factors [119]. Besides, PLS-SEM has proven to be a practical approach for creating theories that involve intricate and explorative models [120]. To evaluate the possibility of the existence of common method bias, a more comprehensive analysis of the data was carried out. In this investigation, the findings produced from un-rotated factor solutions were put through Harman's single-factor test, which is a technique that has been used in the past for academic investigations [121, 122]. The primary objective of this research was to quantify the amount of variables that may be responsible for explaining the differences in the observed data [121].

In this investigation, verbal consent was acquired from survey participants and the study was conducted according to ethical guidelines.

4 Results and data analysis

4.1 Common method bias

Common method bias (CMB) is a severe problem for quantitative researchers since it weakens the integrity of their work. Jordan et al. [123] revealed that the occurrence of CMB arises when data regarding all factors is gathered using the same approach. Therefore, self-reporting questionnaires were the primary technique for collecting data for this study. The possibility of a CMB emergence might be heightened due to the implementation of this technique. Consequently, we executed the results of Harman's single-factor analysis, revealing that CMB is not a significant issue since just one component can explain 31.5% of the variance in the outcome variable, which is less than 50% [124].

4.2 Measurement model

The measurement model was utilized to confirm the authenticity of the latent constructs' consistency and structural properties [125]. Various criteria were employed to estimate the efficacy of the measurement model, including factor loadings, composite reliabilities, convergent validity (as indicated by AVE), and discriminant validity (as presented in Table 2). As a result, the items' accuracy was effectively confirmed by meeting the factor loading criteria, with composite reliability surpassing 0.70 and Cronbach's Alpha exceeding 0.60, ensuring the reliability of the measurements [126]. Moreover, all construct values demonstrate convergent validity greater than 0.50.

We utilized two techniques to establish discriminant validity. Initially, we checked [127]; this suggests that the square root of the AVE for a particular construct should be higher than that of the other constructs, which would indicate a more stable connection. Table 3 demonstrates that the requirement, as mentioned earlier, has been satisfied for all constructions.

Second, we have gone with an HTMT ratio approach. Our study found a range of HTMT values of all constructs between 0.128 and 0.544 (Table 4), which fell below the upper threshold of 0.90 [128]. Furthermore, we employ a bootstrap approach to determine if HTMT differs substantially from 1 for inference.

4.3 Structural model analysis

The value of R2 indicates the proportion of the outcome variable variability that the predictor variable can explain. A summary of the R2 values for all dependent variables can be found in Fig. 2. The R2 value of 0.281 shows that 28.1% of the fluctuations in SSCP can be attributed to the combined influence of three additional variables: COVID-19, advanced technologies, and supply chain collaboration. Therefore, Falk et al. [129] recommended that R2 values should be 0.10 or greater to signify a sufficient amount of explained variance by a specific endogenous construct.

The F2 effect size is a measure that quantifies how much the R2 changes when a specific external factor is taken out of the model. This evaluation helps in making a more precise assessment of the instructive power of each independent variable within the framework. In the PLS path model, omitting an independent variable affects the dependent variable value. A significant influence is indicated by an F2 value of 0.35, moderate by 0.15, and minor by 0.02, as specified in [130]. The F2 effect size in the model quantifies the extent to which a predictor latent variable contributes incrementally to the R2 value of a latent outcome variable. Table 5 presents the effect size values (F2) as 0.181 and 0.053, indicating the magnitudes of the respective effects in the study. Another critical assessment involves determining whether the research model exhibits sufficient predictive significance with respect to the predetermined criterion. Q2 illustrates the predictive potential, and the results presented are obtained from the PLS analysis. When the Q2 value surpasses 0.0, it signifies that the research model can accurately forecast the outcome variable's value. The Q2 values for every dependent variable in the study can be found in Table 5, and all of them exceed zero. This result implies that the model undeniably exhibits valid predictive relevance.

An evaluation of the model's overall performance is carried out by SmartPLS 4 using the standardized root mean square residual (SRMR) index. This is done to evaluate the correctness of the model used for this inquiry and to determine how well it performed overall. According to Hu and Bentler [131], when the value of the SRMR is less than 0.08, it is determined that there is an acceptable match between the model and the data. It is worth noting that an SRMR value of 0.06 represents a significant degree of model quality. Additionally, the normed fitness index (NFI) has attained a score of 0.951, surpassing the 0.90 benchmarks, signifying a favorable model fit, as indicated in [132].

4.3.1 Hypothesis testing

The analytical outcomes for assessing the structural model are presented in Table 6, employing the Smart PLS software. To elucidate the relationships between variables within a specific context, two analytical methods, we utilized correlation analysis and evaluated PLS path coefficients. To enhance the reliability of the β coefficient estimates, we employed the bootstrap resampling approach, allowing for error assessment and determining the statistical significance of these coefficients. To evaluate the precision and establish the statistical significance of the coefficients, bootstrap resampling was used to stabilize the estimates of β coefficients.

The research model was developed and analysed using the SmartPLS software. Figure 2 illustrates the investigation outcomes, while Table 6 presents the examination findings directly related to hypotheses H1 to H3b and indirectly related to hypotheses H4a to H4b and moderation H5a and H5b. Furthermore, the study performed mediation analysis according to the guidelines of Baron and Kenny [133]. In this study, thirteen (9) hypotheses were formulated and subsequently subjected to empirical analysis. All thirteen (9) hypotheses received substantial support, with t-values surpassing the critical threshold of 1.96. We conducted an additional examination to further examine the established assumptions, setting the significance threshold at 5% or a crucial t-value of 1.96, which is also sometimes interchangeably denoted as a p-value of 0.05. A hypothesis is considered statistically validated when its p-value falls below 0.05, and its t-value surpasses 1.96 [134]. The correlation between COVID-19 and SSCP is (β = − 0.217; p ≤ 0.05). The findings indicate a significant and adverse association between COVID-19 and SSCP. Furthermore, the research verified the favourable correlation between COVID-19 and H2a advanced technologies (β = 0.175; p ≤ 0.05) and H2b supply chain collaboration (β = 0.364; p ≤ 0.05) see Table 6. It has also been found that there is a direct correlation between advanced technologies, supply chain collaboration, and SSCP (p ≤ 0.05). Furthermore, in terms of indirect effects, we use the approach of [133]; therefore, the results of this research validated that advanced technologies effectively facilitate the connection between COVID-19 and SSCP (β = 0.067; p ≤ 0.05); supply chain collaboration effectively enables the association between COVID-19 and SSCP (β = 0.062; p ≤ 0.05). Additionally, the moderating role of government support and policies is significant between advanced technologies and SSCP (β = 0.162; p ≤ 0.05) see Table 6 and Fig. 3 and the moderating role of GSP are significant between supply chain collaboration and SSCP (β = 0.027; p > 0.05) see Table 6 and Fig. 4.

5 Discussion

The COVID-19 epidemic has significantly impacted worldwide SC, necessitating the implementation of advanced technology innovations and SCC to confirm the maintenance of SC performance. The present research uses advanced technologies and supply chain collaboration to evaluate the connection between COVID-19 and SSCP. A new conceptual model with numerous hypotheses is presented. The outcomes of this investigation have been classified into two kinds of hypotheses: one showing a direct correlation and the other demonstrating a mediating impact. Based on the findings of our in-depth investigation of the hypothesis, it seems that the COVID-19 epidemic has affected SSCP. These findings are consistent with those found in earlier studies, as described in [19].

The preliminary results for hypotheses \(\left({\text{H}}2\mathrm{a and H}2{\text{b}}\right)\) reveal a positive relationship between COVID-19 and the adoption of advanced technologies and SCC within the sitting of Pakistan. In the case of advanced technologies, our results align with a prior study [135] highlights the use of advanced software and knowledge in handling shocks to the global food system and providing in-time food delivery, minimizing human-to-human and human-to-food contact, making food processing activities smarter, traceability, securely processed food to consumers, and helping to run the SC smoothly during epidemic. Regarding SCC, the collaboration between producers and sellers in the SC mitigates COVID-19 impacts through health guideline adherence and social distancing. Moreover, key factors for boosting customer confidence during the pandemic involve online retail, enforcing health guidelines, and health-oriented promotions [64]. Regarding advanced technologies and SSCP [69] revealed that AI and digital advancement significantly and positively influence SCM in Saudi companies. Furthermore, the most essential benefits of AI and digital advancement are improvements in quality, adaptability, effectiveness, and production. About supply chain collaboration and SSCP [90] enhancing supplementary income, implementing reward and penalty systems, and optimizing synergy coefficients enhance the likelihood of the system progressing towards Pareto optimality and accelerates the achievement of extensive collaboration within the agricultural goods SC primarily led by farmer associations.

This study provides insights into the mediation results for hypotheses H4a and H4b were examined in this study. Moreover, the study employed SEM to explore and confirm the mediating role of advanced technologies and SCC. The findings make it clear that advanced technologies and SCC play a crucial role as mediators in the connection between the COVID-19 epidemic and SSCP. Furthermore, our study aligns with and supports previous literature. Regarding advanced technologies [136] revealed that digital technologies positively impact organization resilience during the epidemic by rapidly processing information within the organization and its SC. About supply chain collaboration [103] revealed the significance of collaborative management of interruptions in the supply chain lies in promoting resilience by improving the exchange of information, coordinating planning efforts, and implementing mechanisms for sharing risks among partners to ensure a consistent provision of vital pharmaceuticals in the face of global crises.

This study investigates the moderation outcomes for hypotheses H5a and H5b. Regarding government support and policies in the relationship between advanced technologies and SSCP, Dubey et al. [105] revealed that during COVID-19, government effectiveness, including measures such as tax credits, postponing interest payments, and investing in digital technologies is essential for strengthening SC resilience through the enhancement of digital flexibility and agility. Government support and policies regarding supply chain collaboration and SSCP are insignificant.

5.1 Theoretical implication

-

This investigation intends to contribute to the current body of knowledge on SSCP and various researchers' calls for more empirical studies in this area [20, 21].

-

This investigation contributes to the existing body of knowledge on supply chains during the epidemic. It presents empirical evidence on how COVID-19 has affected the performance of supply chain companies and SC departments in manufacturing firms in Pakistani setting. This research fills a gap in our understanding of the challenges faced by these sectors. Furthermore, it explores the effects of COVID-19 related to technologies like AI, IoT Blockchain, DT and BDA, and supply chain collaboration.

-

The findings provide insights to uncover underlying mechanism that how SCC with the help of advanced technologies can help to devise those strategies which improve supply chain visibility, agility and resilience to ensure supply chain continuity during pandemic disruptions.

-

This investigation confirmed the association between epidemic and SSCP and the mediating role of advance technologies and SCC and the moderating role of GSP in Pakistani setting.

-

The research adds insights to existing theories using the Resource Based View (RBV), Dynamic Capability View (DCV), and Institutional Theory to examine relationships within supply chains during a global crisis. It highlights the influence of GSP in moderating the impact of technologies on sustainable supply chain performance, offering a deeper understanding of how external factors shape technological outcomes. Additionally, the study explores how advanced technologies and SCC mediate, broadening the framework and providing a comprehensive perspective.

5.2 Practical implication

-

1.

To be ready for a possible future global epidemic, stakeholders in the supply chain must reconsider their strategies to succeed.

-

2.

Innovative technology and automation must be accelerated to increase supply chain reliability, sustainability, and robustness through continuous monitoring, connection, accuracy, and control.

-

3.

Organizations might use supply chain localization, diversity, and regional development to decrease vulnerability in their supply chains.

-

4.

Transitioning to a new outbreak requires coordination and planning among governing bodies and multiple stakeholders.

-

5.

Organizations must utilize this time of uncertainty to explore, innovate, and advance in technological advancement, resulting in good possibilities and, eventually, a competitive edge.

-

6.

The government could provide economic benefits such as tax incentives and financing with zero interest to promote the adoption of smart systems and decentralized ledgers within the logistics and supply chain domains.

-

7.

The implementation of digital systems is inadequate; governmental bodies and corporations should conduct development initiatives to empower their staff with the essential technological competencies to seamlessly operate digital systems.

-

8.

Findings of this study can be generalized to other sectors as well because achieving sustainability with adoption of digital technologies is an emerging theme across industries.

5.3 Limitations

This research acknowledges and highlights several limitations for further investigation. First, cross-sectional data were used in the investigation. Therefore, the use of longitudinal data should be considered for future investigations. Second, data for this study was gathered from SC in Pakistan and the SC department within manufacturing companies. Consequently, for future investigations, it is advisable to collect data from diverse regions and industries to enhance the generalizability of the outcomes. Third, our quantitative study relies on subjective decisions made by participants, and it is essential to acknowledge that researcher assumptions and biases may influence the outcomes. Therefore, for subsequent research endeavors, emphasizing qualitative studies could provide a deeper understanding of the phenomena under examination.

6 Conclusion

In this study, we have explored the link between COVID-19 and SSCP. Our significant outcomes, as presented in response to RQ1, strongly underline the adverse effect of the epidemic on SSCP in Pakistan. These findings highlight that the COVID-19 negative impact on supply chains has been multifaceted, encompassing production, distribution, and logistics disruptions. Lockdowns, travel restrictions, and workforce shortages have impeded the seamless flow of goods and services, resulting in delays, shortages, and increased expenditures. The understanding derived from RQ2, COVID-19, is positively linked to implementing advanced technologies and supply chain collaboration. These outcomes revealed that the challenges presented by the pandemic have motivated organizations to proactively adopt technological innovations and enhance collaboration in their supply chains, recognizing the imperative for adaptability and efficiency to mitigate the impacts of COVID-19 on SC dynamics. Furthermore, RQ3 explores the mediating factors, specifically focusing on how advanced technologies and supply chain collaboration mediate between COVID-19 and SSCP. These findings underscore the important role of advanced technologies and collaborative practices as mediators, acting as essential components in navigating the challenges introduced by COVID-19 and contributing to the overall resilience and sustainability of SC operations. As organizations continue to handle with the evolving landscape shaped by the pandemic, these insights offer valuable considerations for strategic planning and effective management of SC dynamics in the face of unprecedented disruptions. Finally, in RQ4, our outcome highlights that government support and policies are moderators between advanced technologies and SSCP, but an insignificant association is found with supply chain collaboration. Therefore, government support and policies strengthen the relationship between advanced technologies and SSCP in Pakistani companies during COVID-19.

Data availability

The datasets that support the findings of this study are provided within the manuscript and any further details will be made available from the corresponding author upon reasonable request.

References

Remko VH. Research opportunities for a more resilient post-COVID-19 supply chain–closing the gap between research findings and industry practice. Int J Oper Prod Manag. 2020;40(4):341–55.

Sarkis J. Supply chain sustainability: learning from the COVID-19 pandemic. Int J Oper Prod Manag. 2020;41(1):63–73.

IMF, The great lockdown: worst economic downturn since the great depression. 2020.

Linton T, Vakil B. Coronavirus is proving we need more resilient supply chains. Harv Bus Rev. 2020;5:121–9.

Paul SK, Chowdhury P. A production recovery plan in manufacturing supply chains for a high-demand item during COVID-19. Int J Phys Distrib Logist Manag. 2021;51(2):104–25.

Karunathilake K. Positive and negative impacts of COVID-19, an analysis with special reference to challenges on the supply chain in South Asian countries. J Soc Econ Dev. 2021;23(Suppl 3):568–81.

Karmaker CL, et al. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: exploring drivers using an integrated model. Sustain Prod Consum. 2021;26:411–27.

Fortune, 94% of the Fortune 1000 are seeing coronavirus supply chain disruptions. 2020.

Ivanov D, Dolgui A. OR-methods for coping with the ripple effect in supply chains during COVID-19 pandemic: managerial insights and research implications. Int J Prod Econ. 2021;232: 107921.

Min S, Zhang X, Li G. A snapshot of food supply chain in Wuhan under the COVID-19 pandemic. China Agric Econ Rev. 2020;12(4):689–704.

Engelenburg SV, Janssen M, Klievink B. Design of a software architecture supporting business-to-government information sharing to improve public safety and security: combining business rules, events and blockchain technology. J Intell Inf Syst. 2019;52:595–618.

Ali A, et al. How various stakeholder pressure influences mega-project sustainable performance through corporate social responsibility and green competitive advantage. Environ Sci Pollut Res. 2023. https://doi.org/10.1007/s11356-023-29717-w.

Ali A, et al. Managing stakeholder pressure for megaproject success and green innovation: the key role of social responsibility. Eng Manag J. 2023. https://doi.org/10.1080/10429247.2023.2286177.

Cavalcante IM, et al. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. Int J Inf Manage. 2019;49:86–97.

Chaouni Benabdellah A, Zekhnini K, Cherrafi A. Sustainable and resilience improvement through the design for circular digital supply chain. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems: IFIP WG 5.7 International Conference, APMS 2021, Nantes, France, September 5–9, 2021, Proceedings, Part IV. 2021. Springer.

Khanuja A, Jain RK. The conceptual framework on integrated flexibility: an evolution to data-driven supply chain management. TQM J. 2023;35(1):131–52.

Mastroberardino P, et al. New perspectives of experiential tourism: an exploratory analysis of live virtual tours during the COVID-19 outbreak. TQM J. 2021. https://doi.org/10.1108/TQM-06-2021-0164.

El Baz J, Ruel S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int J Prod Econ. 2021;233: 107972.

Basit A, et al. Managing the COVID-19 pandemic: enhancing sustainable supply chain performance through management innovation, information processing capability, business model innovation and knowledge management capability in Pakistan. Sustainability. 2023;15(18):13538.

Moosavi J, Fathollahi-Fard AM, Dulebenets MA. Supply chain disruption during the COVID-19 pandemic: recognizing potential disruption management strategies. Int J Disaster Risk Reduct. 2022;75: 102983.

Khan MR, Manzoor A. Application and impact of new technologies in the supply chain management during COVID-19 pandemic: a systematic literature review. Int J Econ Bus Adm. 2021;9(2):277–92.

Cherrafi A, et al. Digital technologies and circular economy practices: vital enablers to support sustainable and resilient supply chain management in the post-COVID-19 era. TQM J. 2022;34(7):179–202.

Nandi S, et al. Do blockchain and circular economy practices improve post COVID-19 supply chains? A resource-based and resource dependence perspective. Ind Manag Data Syst. 2021;121(2):333–63.

Ralston P, Blackhurst J. Industry 4.0 and resilience in the supply chain: a driver of capability enhancement or capability loss? Int J Prod Res. 2020;58(16):5006–19.

Stević Ž, et al. Supply Chain Management (SCM) breakdowns and SCM strategy selection during the COVID-19 pandemic using the novel rough MCDM model. Complexity. 2023;2023:1–20.

Eisenhardt KM, Martin JA. Dynamic capabilities: what are they? Strateg Manag J. 2000;21(10–11):1105–21.

Garza-Reyes JA. Lean and green–a systematic review of the state of the art literature. J Clean Prod. 2015;102:18–29.

Cherrafi A, et al. Lean, green practices and process innovation: a model for green supply chain performance. Int J Prod Econ. 2018;206:79–92.

Wernerfelt B. A resource-based view of the firm. Strateg Manag J. 1984;5(2):171–80.

Barney JB. Purchasing, supply chain management and sustained competitive advantage: the relevance of resource-based theory. J Supply Chain Manag. 2012;48(2):3–6.

Barney J. Firm resources and sustained competitive advantage. J Manag. 1991;17(1):99–120.

Teece DJ, Pisano G, Shuen A. Dynamic capabilities and strategic management. Strateg Manag J. 1997;18(7):509–33.

DiMaggio PJ, Powell WW. The iron cage revisited: Institutional isomorphism and collective rationality in organizational fields. Am Soc Rev. 1983;48:147–60.

Scott WR, Institutional theory: contributing to a theoretical research program. Great minds in management: the process of theory development, 2005;37(2): 460–84

Kähkönen A-K, et al. COVID-19 as a trigger for dynamic capability development and supply chain resilience improvement. Int J Prod Res. 2021;61:1–20.

Araz OM, Choi TM, Olson DL, Salman FS. Data analytics for operational risk management. Decis Sci. 2020;51(6):1316–9.

Ivanov D. Predicting the impacts of epidemic outbreaks on global supply chains: a simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp Res Part E Logist Transp Rev. 2020;136: 101922.

Sharma A, Adhikary A, Borah SB. Covid-19′s impact on supply chain decisions: strategic insights from NASDAQ 100 firms using Twitter data. J Bus Res. 2020;117:443–9.

Xu Z, et al. Impacts of COVID-19 on global supply chains: facts and perspectives. IEEE Eng Manage Rev. 2020;48(3):153–66.

Singh S, et al. Impact of COVID-19 on logistics systems and disruptions in food supply chain. Int J Prod Res. 2021;59(7):1993–2008.

Modgil S, Singh RK, Hannibal C. Artificial intelligence for supply chain resilience: learning from Covid-19. Int J Logist Manag. 2022;33(4):1246–68.

Nayal K, et al. Exploring the role of artificial intelligence in managing agricultural supply chain risk to counter the impacts of the COVID-19 pandemic. Int J Logist Manag. 2022;33(3):744–72.

Mishra D, et al. Challenges facing artificial intelligence adoption during COVID-19 pandemic: an investigation into the agriculture and agri-food supply chain in India. Sustainability. 2023;15(8):6377.

Zheng Z et al. The role of artificial intelligence technology in improving the resilience of supply chain during COVID-19. In: Advances in artificial systems for medicine and education V. 2022. Cham: Springer International Publishing.

Wamba SF, Queiroz MM. A framework based on blockchain, artificial intelligence, and big data analytics to leverage supply chain resilience considering the COVID-19. Ifac-papersonline. 2022;55(10):2396–401.

Chen X, et al. Internet of Things (IoT)—blockchain-enabled pharmaceutical supply chain resilience in the post-pandemic era. Front Eng Manag. 2023;10(1):82–95.

Yadav S, Garg D, Luthra S. Ranking of performance indicators in an Internet of Things (IoT)-based traceability system for the agriculture supply chain (ASC). Int J Qual Reliab Manag. 2022;39(3):777–803.

Yadav S, Luthra S, Garg D. Internet of things (IoT) based coordination system in Agri-food supply chain: development of an efficient framework using DEMATEL-ISM. Oper Manag Res. 2022;15(1):1–27.

Kumar S, et al. Integrated blockchain and internet of things in the food supply chain: adoption barriers. Technovation. 2022;118: 102589.

Končar J, et al. Setbacks to IoT implementation in the function of FMCG supply chain sustainability during COVID-19 pandemic. Sustainability. 2020;12(18):7391.

Singh S, Gupta A, Shukla AP. Optimizing Supply Chain through Internet of Things (IoT) and Artificial Intelligence (AI). In 2021 International Conference on Technological Advancements and Innovations (ICTAI). 2021.

Omar IA, et al. Blockchain-based supply chain traceability for COVID-19 personal protective equipment. Comput Ind Eng. 2022;167: 107995.

Kazancoglu Y, et al. Resilient reverse logistics with blockchain technology in sustainable food supply chain management during COVID-19. Bus Strat Environ. 2022;32:2327–40.

Iftekhar A, Cui A. A blockchain use case in cold chain to minimize the risk of COVID-19 infection. 2021.

Nandi S, et al. Redesigning supply chains using blockchain-enabled circular economy and COVID-19 experiences. Sustain Prod Consum. 2021;27:10–22.

Paul S, Adhikari A, Bose I. White knight in dark days? Supply chain finance firms, blockchain, and the COVID-19 pandemic. Inf Manag. 2022;59(6): 103661.

Ahmad RW, et al. Blockchain-based forward supply chain and waste management for COVID-19 medical equipment and supplies. IEEE Access. 2021;9:44905–27.

Bag S, et al. How big data analytics can help manufacturing companies strengthen supply chain resilience in the context of the COVID-19 pandemic. Int J Logist Manag. 2021. https://doi.org/10.1108/IJLM-02-2021-0095.

Zhang Q, Gao B, Luqman A. Linking green supply chain management practices with competitiveness during Covid 19: the role of big data analytics. Technol Soc. 2022;70: 102021.

Bag S, et al. Roles of Innovation leadership on using big data analytics to establish resilient healthcare supply chains to combat the COVID-19 pandemic: a multimethodological study. IEEE Trans Eng Manag. 2021. https://doi.org/10.1109/TEM.2021.3101590.

Nisar QA, et al. Sustainable supply chain management performance in post COVID-19 era in an emerging economy: a big data perspective. Int J Emerg Markets. 2022. https://doi.org/10.1108/IJOEM-12-2021-1807.

Chatterjee S, et al. Big data driven innovation for sustaining SME supply chain operation in post COVID-19 scenario: moderating role of SME technology leadership. Comput Ind Eng. 2022;168: 108058.

Hasan R, et al. Critical analysis of the impact of big data analytics on supply chain operations. Prod Plan Control. 2022. https://doi.org/10.1080/09537287.2022.2047237.

Khodoomi MR, Yaghoubi S, Seif M. Effects of COVID-19 outbreak in pricing and collaboration of a health-social dual-channel supply chain. Environ Sci Pollut Res. 2023;30(19):55382–401.

Khuntia J, et al. Integration vs collaborative redesign strategies of health systems’ supply chains in the post-COVID-19 new normal: cross-sectional survey across the United States. JMIR Form Res. 2022;6(6): e35317.

Zhou J, et al. Impacts of IT capability and supply chain collaboration on supply chain resilience: empirical evidence from China in COVID-19 pandemic. J Enterprise Inf Manag. 2022. https://doi.org/10.1108/JEIM-03-2022-0091.

Dash R, et al. Application of artificial intelligence in automation of supply chain management. J Strateg Innov Sustain. 2019;14(3):43–53.

Feng T, Appolloni A, Chen J. How does corporate digital transformation affect carbon productivity? Evidence from Chinese listed companies. Environ Dev Sustain. 2024. https://doi.org/10.1007/s10668-024-04487-8.

Alsharidah YMY, Alazzawi A. Artificial intelligence and digital transformation in supply chain management A case study in saudi companies. In 2020 International Conference on Data Analytics for Business and Industry: Way Towards a Sustainable Economy (ICDABI). 2020. IEEE.

Benzidia S, Makaoui N, Bentahar O. The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technol Forecast Soc Chang. 2021;165: 120557.

Manning L, et al. Artificial intelligence and ethics within the food sector: developing a common language for technology adoption across the supply chain. Trends Food Sci Technol. 2022. https://doi.org/10.1016/j.tifs.2022.04.025.

Dubey R, et al. Impact of artificial intelligence-driven big data analytics culture on agility and resilience in humanitarian supply chain: a practice-based view. Int J Prod Econ. 2022;250: 108618.

De Vass T, Shee H, Miah SJ. The effect of “Internet of Things” on supply chain integration and performance: an organisational capability perspective. Australas J Inf Syst. 2018. https://doi.org/10.3127/ajis.v22i0.1734.

Rejeb A, Keogh JG, Treiblmaier H. Leveraging the internet of things and blockchain technology in supply chain management. Future Internet. 2019;11(7):161.

Gnimpieba ZDR, et al. Using Internet of Things technologies for a collaborative supply chain: application to tracking of pallets and containers. Procedia Comput Sci. 2015;56:550–7.

Hastig GM, Sodhi MS. Blockchain for supply chain traceability: business requirements and critical success factors. Prod Oper Manag. 2020;29(4):935–54.

Gurtu A, Johny J. Potential of blockchain technology in supply chain management: a literature review. Int J Phys Distrib Logist Manag. 2019. https://doi.org/10.1108/IJPDLM-11-2018-0371.

Queiroz MM, Telles R, Bonilla SH. Blockchain and supply chain management integration: a systematic review of the literature. Supply Chain Manag Int J. 2020;25(2):241–54.

Araz OM, et al. Role of analytics for operational risk management in the era of big data. Decis Sci. 2020;51(6):1320–46.

Ivanov D, Dolgui A, Sokolov B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int J Prod Res. 2019;57(3):829–46.

Kim HM, Laskowski M. Toward an ontology-driven blockchain design for supply-chain provenance. Intell Syst Account Finance Manag. 2018;25(1):18–27.

Maheshwari S, Gautam P, Jaggi CK. Role of Big Data Analytics in supply chain management: current trends and future perspectives. Int J Prod Res. 2021;59(6):1875–900.

Gunasekaran A, et al. Big data and predictive analytics for supply chain and organizational performance. J Bus Res. 2017;70:308–17.

Roßmann B, et al. The future and social impact of Big data analytics in supply chain management: results from a Delphi study. Technol Forecast Soc Chang. 2018;130:135–49.

Bag S, et al. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour Conserv Recycl. 2020;153: 104559.

Nicoletti B, Appolloni A. A framework for digital twins solutions for 5 PL operators. Technol Soc. 2024;76: 102415.

Susanto E, et al. The impact of collaborative networks on supply chain performance: a case study of fresh vegetable commodities in Indonesia. AGRARIS J Agribus Rural Dev Res. 2023;9(1):79–99.

Hosseinnezhad D, Nugroho YK, Heavey C. Horizontal collaboration between suppliers to mitigate supply chain disruption: a secure resource sharing strategy. Comput Ind Eng. 2023;177: 109088.

Goenka R, Vijayaraghavan T, Israel D. Impact of supply chain human capability, responsive design, and collaboration on supply chain resilience. Int J Strat Decision Sci. 2021;12(1):37–60.

Huo Y, et al. The collaboration mechanism of agricultural product supply chain dominated by farmer cooperatives. Sustainability. 2022;14(10):5824.

Belhadi A, et al. Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: an empirical investigation. Ann Operat Res. 2021. https://doi.org/10.1007/s10479-021-03956-x.

Ding X, et al. Digital transformation, ESG practice, and total factor productivity. Bus Strat Environ. 2024. https://doi.org/10.1002/bse.3718.

Ma L, et al. Factors of green innovation: the role of dynamic capabilities and knowledge sharing through green creativity. Kybernetes. 2022. https://doi.org/10.1108/K-06-2022-0911.

Wang M, Pan X. Drivers of artificial intelligence and their effects on supply chain resilience and performance: an empirical analysis on an emerging market. Sustainability. 2022;14(24):16836.

Dubey R, et al. Facilitating artificial intelligence powered supply chain analytics through alliance management during the pandemic crises in the B2B context. Ind Mark Manage. 2021;96:135–46.

Goodarzian F, et al. Designing an integrated responsive-green-cold vaccine supply chain network using Internet-of-Things: artificial intelligence-based solutions. Ann Oper Res. 2022. https://doi.org/10.1007/s10479-022-04713-4.

Yadav S, Luthra S, Garg D. Modelling Internet of things (IoT)-driven global sustainability in multi-tier agri-food supply chain under natural epidemic outbreaks. Environ Sci Pollut Res. 2021;28:16633–54.

Yadav S, Luthra S, Garg D. Internet of things (IoT) based coordination system in Agri-food supply chain: development of an efficient framework using DEMATEL-ISM. Oper Manag Res. 2020;15:1–27.

Nabipour M, Ülkü MA. On deploying blockchain technologies in supply chain strategies and the COVID-19 pandemic: a systematic literature review and research outlook. Sustainability. 2021;13(19):10566.

Spieske A, Birkel H. Improving supply chain resilience through industry 4.0: a systematic literature review under the impressions of the COVID-19 pandemic. Comput Ind Eng. 2021;158: 107452.

Yamin MA. Investigating the drivers of supply chain resilience in the wake of the COVID-19 Pandemic: empirical evidence from an emerging economy. Sustainability. 2021;13(21):11939.

Yu W, et al. Role of big data analytics capability in developing integrated hospital supply chains and operational flexibility: an organizational information processing theory perspective. Technol Forecast Soc Chang. 2021;163: 120417.

Takawira B, Mutambara E. COVID-19 and emerging markets: a strategic framework for pharmaceutical supply chains. 2023.

Sartika W, et al. The resilience of rendang industries during and after covid 19 pandemic: a marketing collaboration and supply chain management approach. Adv Anim Vet Sci. 2023;11(6):998–1005.

Dubey R, et al. Dynamic digital capabilities and supply chain resilience: the role of government effectiveness. Int J Prod Econ. 2023;258: 108790.

Goel RK, Saunoris JW, Goel SS. Supply chain performance and economic growth: the impact of COVID-19 disruptions. J Policy Model. 2021;43(2):298–316.

Chebo AK, Dhliwayo S. Scientific mapping and thematic progression of digitalization of social entrepreneurship in developing countries. Sustain Futures. 2024;7: 100153.

Paul SK, et al. Supply chain recovery challenges in the wake of COVID-19 pandemic. J Bus Res. 2021;136:316–29.

Adejare BO, et al. COVID-19 pandemic and business survival as mediation on the performance of firms in the FMCG-sector. Athens J Bus Econ. 2022;8(3):239–60.

Frank AG, Dalenogare LS, Ayala NF. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int J Prod Econ. 2019;210:15–26.

Cao M, Zhang Q. Supply chain collaborative advantage: a firm’s perspective. Int J Prod Econ. 2010;128(1):358–67.

Alkahtani A, Nordin N, Khan RU. Does government support enhance the relation between networking structure and sustainable competitive performance among SMEs? J Innov Entrepreneurship. 2020;9(1):14.

Jeong H, et al. What types of government support on food SMEs improve innovation performance? Sustainability. 2021;13(16):9461.

Sharma M, et al. Developing a framework for enhancing survivability of sustainable supply chains during and post-COVID-19 pandemic. Int J Log Res Appl. 2022;25(4–5):433–53.

Altay N, et al. Agility and resilience as antecedents of supply chain performance under moderating effects of organizational culture within the humanitarian setting: a dynamic capability view. Prod Plan Control. 2018;29(14):1158–74.

Prasojo LD, et al. Dataset relating to the relationship between teacher self-concept and teacher efficacy as the predictors of burnout: a survey in Indonesian education. Data Brief. 2020;30: 105448.

Yasri Y, et al. Price perception and price appearance on repurchase intention of Gen Y: do brand experience and brand preference mediate? Heliyon. 2020;6(11): e05532.

Gudergan SP, et al. Confirmatory tetrad analysis in PLS path modeling. J Bus Res. 2008;61(12):1238–49.

Fornell C, Bookstein FL. Two structural equation models: LISREL and PLS applied to consumer exit-voice theory. J Mark Res. 1982;19(4):440–52.

Nitzl C. The use of partial least squares structural equation modelling (PLS-SEM) in management accounting research: Directions for future theory development. J Account Lit. 2016. https://doi.org/10.1016/j.acclit.2016.09.003.

Koh J, Kim Y-G. Knowledge sharing in virtual communities: an e-business perspective. Expert Syst Appl. 2004;26(2):155–66.

Leimeister JM, Sidiras P, Krcmar H. Exploring success factors of virtual communities: the perspectives of members and operators. J Organ Comput Electron Commer. 2006;16(3–4):279–300.

Jordan PJ, Troth AC. Common method bias in applied settings: the dilemma of researching in organizations. Aust J Manag. 2020;45(1):3–14.

Hair J Jr, et al. A primer on partial least squares structural equation modeling (PLS-SEM). Cham: Sage publications; 2021.

Mardani A, et al. Evaluation of green and sustainable supply chain management using structural equation modelling: a systematic review of the state of the art literature and recommendations for future research. J Clean Prod. 2020;249: 119383.

Hair JF, et al. Multivariate data analysis. Boston: Cengage; 2019.

Fornell C, Larcker DF. Evaluating structural equation models with unobservable variables and measurement error. J Mark Res. 1981;18(1):39–50.

Henseler J, Ringle CM, Sarstedt M. Testing measurement invariance of composites using partial least squares. Int Market Rev. 2016. https://doi.org/10.1108/IMR-09-2014-0304.

Falk RF, Miller NB. A primer for soft modeling. Akron: University of Akron Press; 1992.

Cohen J. Statistical power analysis for the behavioral sciences New York. New York: Academic; 1988. p. 54.

Hu L-T, Bentler PM. Fit indices in covariance structure modeling: sensitivity to underparameterized model misspecification. Psychol Methods. 1998;3(4):424.

Hair JF, et al. When to use and how to report the results of PLS-SEM. Eur Bus Rev. 2019;31(1):2–24.

Baron RM, Kenny DA. The moderator–mediator variable distinction in social psychological research: conceptual, strategic, and statistical considerations. J Pers Soc Psychol. 1986;51(6):1173.

Hair JF Jr, et al. Partial least squares structural equation modeling (PLS-SEM). Eur Bus Rev. 2014;26(2):106–21.

Chitrakar B, Zhang M, Bhandari B. Improvement strategies of food supply chain through novel food processing technologies during COVID-19 pandemic. Food Control. 2021;125: 108010.

Cui L, et al. Investigating the relationship between digital technologies, supply chain integration and firm resilience in the context of COVID-19. Ann Oper Res. 2023;327(2):825–53.

Adejare BO, et al. COVID-19 pandemic and business survival as mediation on the performance of firms in the FMCG-sector. Athens J Bus Econ. 2021;7:1–22.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Contributions

AJ: writing original manuscript; reviewing literature; creating an adapted analytical framework; AB: collecting data; formal analysis; FE: bibliographical guidance; suggestions on the design of the analytical framework, methodology, software, investigation. AH: bibliographical guidance; data curation, reviewing manuscripts; ZJF: Funding acquisition, methodology, writing reviews, reviewing manuscripts; editing, validation, visualization; MBH: conceptualization, methodology, resources, funding acquisition, project administration, review of final version, editing, validation and supervision. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The study was conducted according to the guidelines of the Declaration of Helsinki and approved by the Review Ethics Board of University of Okara, with ethical approval no. Uo-1763-22.

Consent to participate

Respondents, and key participants were informed and verbal consent was made before involving them in the survey.

Competing interests

The author(s) declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Questionnaire | ||||||

|---|---|---|---|---|---|---|

Scale: 1 = Strongly Disagree, 2 = Disagree, 3 = Neutral, 4 = Agree, 5 = Strongly agree | 1 | 2 | 3 | 4 | 5 | |

How did COVID-19 outbreak negatively affect Supply Chain? | ||||||

1. The COVID-19 virus is present in all parts of the country? | [137] | |||||

2. The COVID-19 virus made a severe impact on the way we conduct business? | ||||||

3. Did Covid-19 negatively affect Overall operations? | [18] | |||||

4. Did Covid-19 negatively affect Lead time for delivery? | ||||||

5. Did Covid-19 negatively affect Purchasing costs for supply? | ||||||